As an amazon associate, I earn affiliate commissions from qualifying purchases.

How to Adjust Torque on Air Impact Wrench: 2 Process & Some Tips

An air impact wrench is the kind of equipment that can make your life easier when you need to loosen the stubborn bolts and nuts. Adjusting torque on this equipment is mandatory, or else you won’t get accurate results.

Torque is a twisting force that requires power during its working process.There are people who have failed to calibrate it, and due to that, they have ended up with damaged lugs, screws, and even work surfaces.

After reading this portion, you might ask yourself, ‘How to adjust torque on air impact wrench?’ Don’t worry, because we have got your back.

From the following article, you will get all the information regarding this question. Go through them so that you can avoid this kind of problem from happening.

The Ways You Can Do It

The good news is you can get the job done in two ways. This might look a bit challenging at the beginning, but with proper knowledge, you will have all the confidence that you need in the first place.

All the procedures are written in an easier format for your ease so that you don’t face any problem in any section. Check it out.

Process 1: Regulating the Line Compression

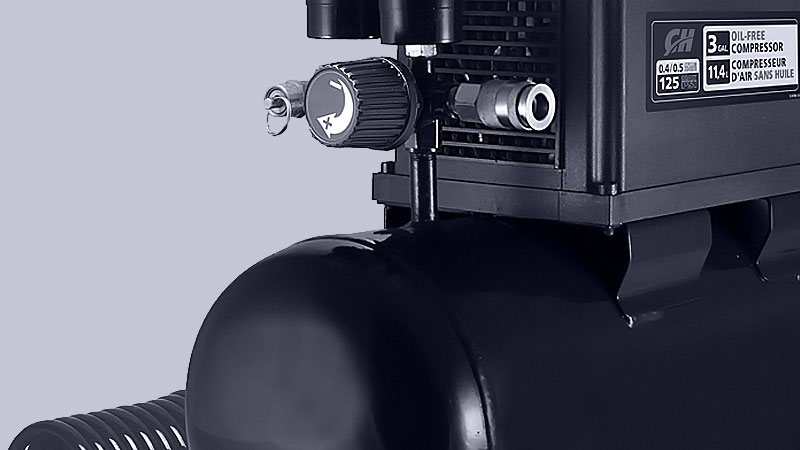

Yes, with proper control on the line compression, you can easily adjust the torque. For this process, you have to activate the compressor and let it run until it had arrived at the pressure of the valve.

With the help of a compressor, connect the impact wrench and do it with the use of an air hose.

Now you can control the pressure regulator by decreasing the working compression that is present in the line.

Congrats! You are done with adjusting the torque.

Process 2: Regulating the Tool Compression

Fortunately, you can get the same result if you can regulate the tool compression properly.

The way you can do this is by connecting the tool air regulator with your air impact wrench. Like the previous process, you will need an air hose. Take it and fix it with the regulator. Make sure you are not in a hurry, or else your whole work will be in jeopardy.

Now you are all set to control the tool pressure to adjust the torque.

Some Tips

Before you dive into this process, it will be best that you take some things into consideration. Here are all the necessary tips that will be your ultimate savior all the time.

Tip 1: Choose Wisely

Reducing the compressors’ air pressure also reduces the compressions’ quantity. This shows that they are directly proportional. If you have to use a single compressor to operate multiple tools simultaneously, you should definitely take the help of a tool air regulator.

Don’t hesitate to go for this option because it will simply add value to your work and the result.

Tip 2: Understand the Dependency of the Amount of Torque

If you apply the above process, it will decrease the amount of torque that is going to be produced by the impact wrench. Remember, the wrench’s maximum amount of torque is completely dependent on the compressor’s working flow and the manufacturers’ pressure rating.

Tip 3: Take Necessary Steps When You Need Narrow or Finite Tolerance

In situations where you need narrow or finite tolerances, you then have to check your settings with a wrench that has calibrated torque.

Tip 4: Always Wear Protective Gears

Before you start working, make sure you are using the proper protection gears for your eyes as well as your ears because your vision and hearing are the most vulnerable in this task. If you prefer, you can even wear gloves (optional).

Tip 5: Give Full Focus on the Task

Avoid distractions during this task. If you have kids, keep them busy and don’t let them present in your working station.

Tip 6: Never Cross the Maximum Operating Pressure

For every tool, the manufacturer has given a specific operating pressure. It is strictly advised that you avoid exceeding the maximum pressure in order to save the tools from getting damaged.

Tip 7: Carefully Read the Instruction Manual

You can’t use the same torque on all the fasteners because different fasteners come with their own unique characteristics such as bolt length, presence of gasket between the alloys and parts, and many more. Always read the instruction that normally comes with the packaging.

Tip 8: Use a Clever Approach

If the manual in your case gives you the value that is related to dry and clean parts, but the bolt and threads are oiled in your situation — no problem. Just decrease the torque between 15 and 25 percent of its original value, and you will be all set.

Tip 9: Check your budget

There are tons of wrenches available in the market and online stores. If your budget is not huge and you are looking for one that is quite affordable and efficient, don’t hesitate to select the top air impact wrench for under $100.

Conclusion

There you go, all about the answers to the question ‘How to adjust torque on air impact wrench?’

If you still have confusion, consult with a professional. Their advice will surely help you out in the long run.

Best of luck! And have a good day.